Tool developed by Singapore surgeon’s team makes knee replacement safer, more precise

Sign up now: Get ST's newsletters delivered to your inbox

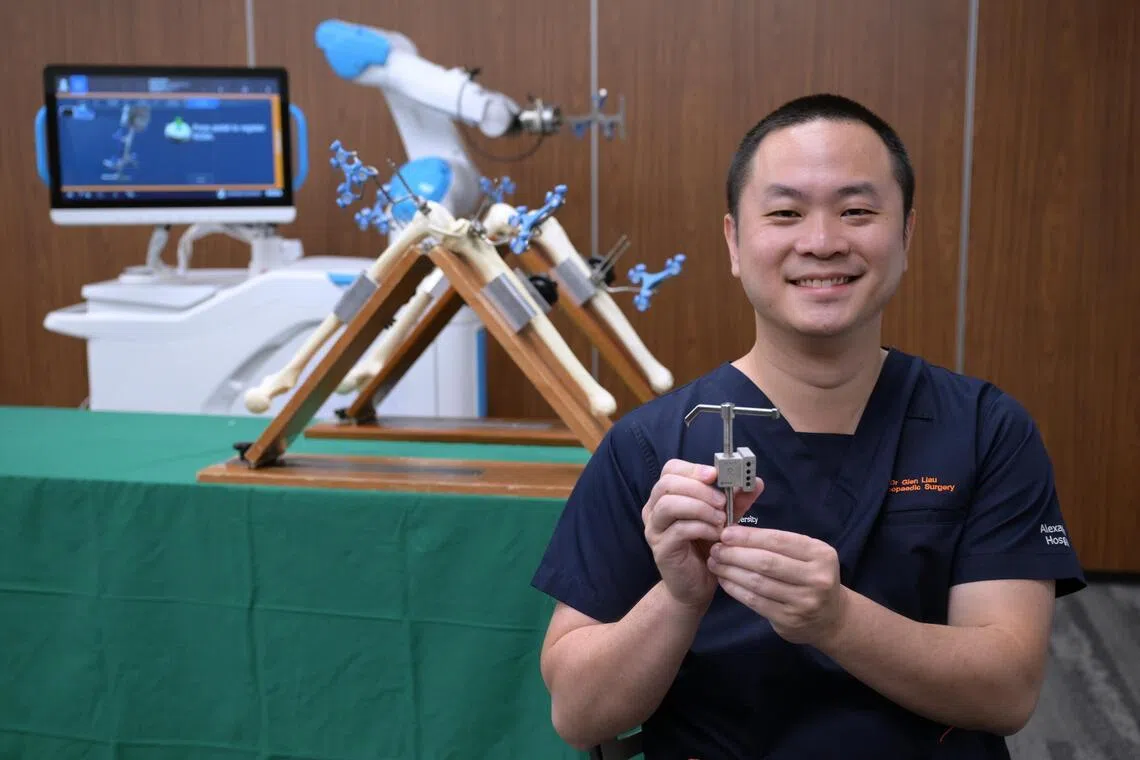

Orthopaedic surgery consultant Glen Liau led the team that came up with a pin guide tool that allows for better single-incision robotic total knee arthroplasty.

ST PHOTO: NG SOR LUAN

- Robotic knee surgeries risk fractures from tracker pins. Prof Liau's team developed a less invasive tool to precisely guide pins, significantly reducing complication risks.

- The patented tool, utilising the "Liau inflection point", ensures accurate pin placement within 1mm/1 degree, reducing fracture rates from 80% to 30% in lab tests.

- Successfully used on over 200 patients, validated in a study, and combined with an AI algorithm, this method aims to halve surgery time and improve patient outcomes.

AI generated

SINGAPORE – Robot-assisted total knee arthroplasty, or knee replacement surgery, has grown in popularity worldwide due to its greater precision and improved outcomes, but it also risks complications such as fractures.

This is because up to four tracker pins are drilled into the thigh and shin bones to enable the robot to map the bones precisely in real time and guide the surgeon.

Inserting pins at multiple points can weaken the bones, making them more likely to fracture.

Other risks include wound infections and nerve injuries, noted Adjunct Assistant Professor Glen Liau, a consultant at Alexandra Hospital’s orthopaedic surgery department.

To reduce these risks, a team led by Prof Liau developed a tool known as a jig, which is less invasive than the conventional method.

The tool requires just a single incision on the knee through which all the pins are drilled. This lowers the risk of bone fracture, bleeding and infection associated with additional cuts.

“In addition, the surgical grade stainless steel jig enables precise control of pin depth and angle, ensuring consistent and accurate placement,” said Prof Liau.

While surgeons typically select the points of incision by eye, Prof Liau identified a specific position – now called the Liau inflection point – that can be used consistently for every patient to guide pins to the exact locations.

This method eliminates estimation, allowing the surgeon to insert the pins with precision, accurate to within 1mm and one degree.

“With this accuracy, we have also been able to shorten our main central incision, making our operations even more minimally invasive,” he said.

Laboratory tests showed that the traditional method caused fractures 80 per cent of the time, compared with only 30 per cent using the new method.

The procedure was validated in a study of 102 patients using major robotic total knee arthroplasty systems, with the findings published in the peer-reviewed journal Arthroplasty in 2025.

In October, a patent for the tool – which has been used on more than 200 patients in Singapore since 2023 – was successfully filed with the Intellectual Property Office of Singapore.

The project was recognised at the 2025 annual meeting of the American Association of Hip and Knee Surgeons in October, and won first prize at the Thai Hip and Knee Society annual meeting in December.

Such tools are necessary as robotic total knee replacement operations become more common, said Prof Liau, noting that they now comprise 13 per cent of all such procedures.

“I’ve been using robotic technology for all my patients in the past 3½ years,” he said.

Prof Liau also developed an artificial intelligence (AI) algorithm that integrates with the robot’s software to determine the optimal positioning of implants and cut surgery time by half.

Among those who have undergone the new procedure is 72-year-old Madam Law Lai Tee. The retired mother of two had severe osteoarthritis, which caused her left knee to curve 26 degrees inward – a condition known as severe valgus deformity. It accounts for less than 0.5 per cent of knee replacement operations.

Before the surgery, every step was painful and unstable, she said.

Standard implants could not be used for this rare condition as there was a small margin of error, requiring a more constrained approach, said Prof Liau.

Madam Law underwent surgery in November 2025 and was recovering well a month later.

“Today, my leg is straight again. The relief is not just in the knee, but knowing I didn’t have extra wounds to heal from and worry about,” she said.

Another patient, Madam Nor Aini Abdullah, 85 – older than the typical knee replacement patient, who is about 68 – can now run errands independently after her procedure in October.

Prof Liau said: “In sharing our techniques, inventions and findings, we hope that more patients will benefit from safer and better knee replacements in future.”

Madam Nor Aini Abdullah (left) underwent robotic total knee replacement surgery in October 2025 and Madam Law Lai Tee (right) underwent the same surgery in November 2025. She had severe valgus deformity from osteoarthritis.

ST PHOTO: NG SOR LUAN